The Piping Profile in general can be considered

as a complex and rigid piping network consisting of various piping

components, which have different diameters and weights. At the same time the

above network is also subjected

to temperature change.

A satisfactory design of the Piping System should therefore give a careful consideration to achieve the above requirement. This is generally accomplished by providing external attachments (known as pipe supports) at various locations of the piping profile.

PURPOSE OF PIPE SUPPORTS

TO SUPPORT WEIGHT OF PIPE-DURING OPERATION

& TESTING

Supports are required to support the line during

all conditions i.e. during operation as well as during testing. In case of vapour line this difference will be very large due to hydro testing. Supports

should be designed for this load

Some times line is capable of having longer span but load coming on the support may be very large (especially with large dia pipe lines). Then to distribute the load uniformly, more number of supports should be provided with smaller span.

TO TAKE 'EXPANSION

LOAD'

TO TAKE 'WIND LOAD'

Wind introduces lateral load on the line. This load is considerable especially on large diameter pipe. This tends to sway the line from its normal position and line must be supported guided against it. In case of large diameter overhead lines, supported by tall support extended from floor, wind load introduces large bending moment and should be considered critically.

TO TAKE 'EARTH QUAKE

LOAD'

The earthquake is normally associated with horizontal acceleration of the order of 1 to 3 m/sec2. This is around 10% to 30% of the gravitational

acceleration and introduces horizontal force of about 10 to 30% of the

vertical load (or supported mass). While designing support this should be taken care.

TO ABSORB 'VIBRATION

OF PIPING SYSTEM'

When the pipe is subjected to moving machinery or pulsating flow or very high velocity flow, pipe may start vibrating vigorously and ultimately may fail, particularly if span is large. To avoid this it may be required to introduce additional supports at smaller span apart from other requirements. It may not take axial load, but must control lateral movements.

TO HAVE 'NOISE CONTROL

In most of the plants, noise is resulting from vibration and if such vibrations are controlled, noise is reduced to great extent. In such lines, between clamp (i.e. support) and pipe, asbestos cloth is put to absorb vibration and avoid noise.

TO TAKE 'HYDRAULIC

THRUST IN PIPING

The hydraulic thrust in the pipeline is present at certain point such as pressure reducing valve, relief valve, bellows etc.

If the control

valve has large pressure differential and line size is more, then this force can be very high. The support should

be provided and designed to take this load, otherwise this will load the piping

system and may cause

failure.

TO SUPPORT THE SYSTEM

DURING 'TRANSIENT PERIOD OF PLANT AND STANDBY CONDITION

Transient condition refers to the start-up or

shutdown condition in which one equipment may get heated up faster and other one get heated

slower. Due to this the expansion of one equipment which in normal operation will get nullified, may not get nullified and exert thermal

load on supports.

Standby condition is also similar. If there are

two pumps, one being standby and both connected in parallel (as shown),

design and operating

temp. of both the connections will be same.

But the expansion of two parallel legs will not be nullified

because at a time only one leg will be hot and another being cold.

TO SUPPORT THE SYSTEM

DURING 'MAINTENANCE CONDITIONS'

When for maintenance certain equipment or

component like valve is taken out, remaining system should not be

left out unsupported.

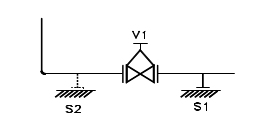

Referring to the FIG, support 'S1' will be

sufficient but when valve 'V1' is taken out for maintenance there will

not be any support for vertical leg. Therefore second support 'S2' may be

required to take care of such condition.

TO SUPPORT THE SYSTEM

DURING 'SHUTDOWN CONDITIONS

In shutdown condition all equipment may not be in the same condition

as in operating condition.

For example, refer the pump

discharge line in FIG, Point A is resting, Point B & C are spring supports and Point D is the pump discharge nozzle. The springs

are, designed based

on weights considering the weight of fluid as

well as pipeline and thermal movements. But during shutdown condition the fluid

may be drained and the pipe becomes lighter. Hence the spring will give

upward reaction and shall load the nozzle 'D' beyond permissible limit.

TO SUPPORT THE SYSTEM FOR ERECTION CONDITIONS

Erection condition can be different than the

operating condition which should be considered while designing supports.

Erection condition can be different than the

operating condition which should be considered while designing supports.

For example for normal operation a long vessel

supported by three supports, S1, S2 & S3 is

shown in FIG-5.

If support S2 is higher, than all load will act at S2 only. During erection if

level of S2 is lower then entire load will be divided

into two supports

S1, S2 only. Therefore foundation of S1, S2 & S3 should be capable

of taking such conditions.

A pipe line supported by S1, S2 & S3 taken

from vessel is shown in above FIG - 6. During operation there will be no weight at S2 & S3 (as it is only guide), but wind condition

will be there. Loads due to such conditions must be considered while designing the supports.

CLASSIFICATION OF PIPE SUPPORTS

Broadly the pipe supports are

classified in three groups as per following details / functions :

General details

Construction

details

Functions ie.

purpose

CLASSIFICATION AS PER

GENERAL DETAILS

A pipe line need to be supported from a

foundation or an structure. The piping loads will be acting on these foundations

/ structures. Since these foundations / structures are built on ground, they

will exert an equal and opposite reaction, while supporting the pipe. In a pipe support, there will be some parts of

support arrangement which is directly attached to the pipeline and there will be some other parts which shall be directly attached to the foundation / structure supporting

the pipe.

As per this general

detail the support

is classified as :

PRIMARY SUPPORTS :

It is the parts of support

assembly which is directly connected to the pipe.

SECONDARY SUPPORTS :

It is the parts of support assembly which is directly connected

to the foundation / structure

and is supporting the primary

support attached to the pipe line.

CLASSIFICATION AS PER CONSTRUCTION :

Based on construction details,

pipe supports are broadly classified in three types,

as

-

RIGID SUPPORTS

-

ELASTIC SUPPORTS

-

ADJUSTABLE SUPPORTS

These are described below in brief.

RIGID SUPPORTS

:

This type of support arrangement is generally

very simple and has maximum use in piping. It does not have adjustibility to

the erection tolerances. It will directly rest on foundation or structure which

is supporting the pipe. Common type of RIGID SUPPORTS are shoe

type (welded), shoe type (with clamp) Trunnion

type, valve holder type, support

brackets (Secondary Support). These are described under the topic 'Supports

Generally used'.

ELASTIC SUPPORT :

This type of support is commonly

used for supporting hot piping.

It shall be able to support pipes even when the pipe is moving up or down at support point.

Common type of elastic supports are variable

type spring supports, constant type spring supports. These are described

under the topic 'Supports generally used '.

ADJUSTABLE SUPPORTS :

This type of support is Rigid type in construction but is has few nuts and bolts arrangements for adjusting the supports with respect to the actual erected condition

of pipe. The support can be adjusted for the erection tolerances

in the piping. These are required for a better supporting needs

at critical locations

of pipe supports.

Mostly all type of rigid supports can be modified

by using certain type of nuts and bolts arrangement, to make it as an Adjustable support.

Only a typical type of

adjustable support is described under the topic 'Supports Generally used.'

CLASSIFICATION AS PER

FUNCTION (i.e. PURPOSE)

Pipe supports classified as per functions are

summarised in the Table.. These are shown along with its basic

construction, the symbols

generally used and type of restraints it offers to the piping

system.

The supports classified as per function

are further described as follows :

LOOSE SUPPORT

:

This is most commonly used support meant for

supporting only the pipe weight vertically. It allows pipe to move in axial as well as transverse direction

but restricts only the vertical

downward movement.

LONGITUDINAL GUIDE :

This type of support is used to restrict the movement of pipe in transverse direction

i.e. perpendicular to length of pipe but allow movement

in longitudinal direction. This is also a commonly

used type of support.

Generally it is used along with Loose support.

TRANSVERSE GUIDE :

This type of support is used to restrict the

movement of pipe in longitudinal (axial ) direction but allows the pipe

to move in transverse direction. This is also referred as 'AXIAL STOP'. This

type is less used as compared to above two types. Generally it is

used along with Loose support.

FIXED POINT / ANCHOR :

FIX POINT type of support is used to restrict

movements in all three directions.

ANCHOR type of support is used to restirct movement in all three

directions and rotation also in these three

directions.

Non-Welded Type (FIX POINT) :

This can be considered as a combination of longitudinal and transverse guide.

This type resist

only the linear movements in all directions but not the rotational movements. This avoids heavy loading of support as well

as pipe. Therefore this type of support is preferred over welded type.

Welded Type (ANCHOR)

This type of support prevents total movements

i.e. linear as well as rotational. This type of support is used when it is absolutely essential to prevent

any moment/force being transferred further.

It causes heavy loading

on support as well as pipe.

LIMIT STOP :

As name itself

indicates it allows

pipe movement freely upto a certain limit and restricts any further movement.

This is useful

when total stops causes excessive loading on piping

and support or nozzle.

This type of support should be used selectively, because

of stringent and complicated requirements of design, erection and operation.

SPECIAL SUPPORTS :

When we need a pipe support

whose construction or functional details

are different from the available details, then a special support detail sketch is prepared. The

functions of this support can be any combination

of above functions.

SUPORT DETAILS

GENERALLY USED :

Following are the type of supports

generally used in a project.

SHOE TYPE SUPPORT :

Shoe type support are the supports used maximum in any project.

These can be directly welded to pipe or can be welded

to a clamp put around

pipe. Shoe type supports are used for supporting lines with insulations.

Basically the detail is as follows :

Basically it is used as a Loose support. With slight addition of details it can be also used as a guide, fix point, anchor, transverse guide, limit

stops. It can also be modified to be used as Adjustable supports.

These are primary supports

and will be supported on secondary supports

(i.e. Foundation or structure)

TRUNNION SUPPORTS :

In this type of support,

a dummy pipe is welded

to the main line so that the dummy pipe becomes a rigid part of

the main pipe line. Now this pipe is suitably supported on a secondary support

(Foundation or a structure) The basic detail is as follows :

As per piping requirement, the TRUNNIONS can be

VERTICLE (as shown in FIG-9) or can also be in HORIZONTAL. These are used for loose

supports, guides, transverse guides, fix points, achors as well as adjustable supports.

HANGER SUPPORT

:

As the name suggest,

in a hanger suport the pipe is hung from an structure

using a hanger rod.

As is clear from the FIG.-10, pipe can move in

all direction except downwards. A hanger support generally uses a clamp

on the pipe. When a turn buckle is used than the support is adjustable type.

Hanger rods are used as a loose supports, which is free to lift up.

SPRING SUPPORT

:

Spring Support is a special

type of support which is used in the situations where the support

point on the pipe is expected to move up or down during the operating condition

(due to thermal growth ) from its installed position without spring, the pipe will

therefore either lift from secondary support or will make an unsuccessful

attempt to press against the rigid secondary support. Both are detrimental to

the structural integrity of the Piping System.

The spring support basically employs a spring

element, which can get compressed or open up depending upon the thermal movement at the support

point of pipe. By doing so it takes the vertical load of the piping under

both the situations. From the utility point, spring supports are classified as

Variable spring type & constant spring type. As per arrangement

spring support can be classified as supporting the pipe from under (i.e resting

type) or as supporting the pipe from above (i.e.

hanger type).

VARIABLE SPRING SUPPORT :

This basically consists

of spring which can get compressed or expanded according

to thermal expansion. However this movement causes increase or decrease in supporting

force depending on its stiffness and this differential load is transferred to the

pipe, but this is much less than that would be with rigid support or rigid hanger.

HANGER TYPE (VARIABLE)

In hanger type variable spring

support, the pipe is hung from the secondary support

using hanger type spring, as shown.

CONSTANT SPRING SUPPORTS :

In variable spring support variability factor

is maintained generally within 25%. When the vertical movement of support

point is large and/or a very less magnitude of differential force from cold to hot condition

is permissible, then constant type of support is used. This is also basically

spring support but load is supported by it through

a lever mechanism in such a way that when spring gets compressed effective leverage is reduced and vice-versa. So that net supporting force

remains constant, i.e. without any load fluctuation.

ADJUSTABLE SUPPORT :

As the name suggest, this type of support is capable of adjustment at site to accommodate erection

tolerances of piping. Basically

all type of support can be easily modified and made adjustable. A typical

example for support at pump suction is shown below.

U-BOLT TYPE SUPPORT :

U-bolt type support

is one of the most simplest and extensively used primary support

item for supporting un- insulated piping.

These are generally

used as GUIDES. These can be used conveniently as fix points for smaller

size, non- insulated piping. For large dia pipes, its

use as fix point is generally avoided.

SPECIAL SUPPORTING

CASES

Few special supporting cases near pumps, tall vessels and exchangers are described as follows :

1.To avoid loading of suction nozzle due to control valve weight, which is nearby, if we provide a trunnion (non insulated as per normal practice) to take weight of control valve, then during operation such nozzle will move up and lift the trunnion off its base. This will load the nozzle and purpose of trunnion will not get served.

2.This can be avoided by insulating trunnion, so

that it will remain hot and will expand upwards and will provide resting.

Thus in most cases, the nozzle loading

can be controlled without use of spring supports, near pump nozzles.

3.When supporting a line coming from top nozzle of a short vessel as shown in , if the temperature and material of the vessel and pipe line is same, then the line may be supported at ground level.

When supporting a line coming from a tall vessel

and the line temperature is different from vessel, it should be supported from

vessel at the neutral point with respect to vessel. Such point is normally near

the nozzle itself The pump

should be connected through flexible loop connection to avoid nozzle loading.

Alternatively

line may be supported at bottom (near pump) and loop may be provided

at top as shown in FIG.

4.While supporting suction and discharge piping

to a pump, the supports being provided should be sufficient to take care the maintenance requirements of

the pumps i.e. if the valves / strainers, on the pumps are taken out for maintenance, the lines should

remain supported.

5. In

comparatively larger size pipes when a resting support is required at location

"A", then an adjustable type supports should be provided. This is

necessary due to the maintenance requirements - such as changing of gaskets,

etc.

FIXED SADDLE LOCATION FOR EXCHANGERS

A horizontal equipment will normally have two supports, saddle type. Normally one of them is made fixed and the other sliding type.Enclosed sketch showing a few typical cases will make the concept clear.

1.For the long vessel as shown in figure 28, selection of fixed saddle is decided by stiff connection 'A'. Now if pumps are located at 'B' then expansion of 15mm (vessel expansion) and 5mm (pump line expansion) i.e. total 20mm will load the pump nozzle excessively.

If pumps are located at 'C' then expansion of the pump line will nullify the vessel expansion, since both are in the same direction

hence this type of arrangement should be preferred if possible.

2.In such case if saddle 'A' is fixed in figure 29, total expansion

of 13m will be required

to be absorbed by pipe line.

If saddle 'B' is fixed

then vessel expansion of 4m will be nullified by pipeline expansion of 4m and only differential expansion of 9 m will be

required to be absorbed.

3.In such case by looking at line size in figure

30, one may think that more attention be given to 20" connection. But

looking correctly, saddle selection does not make any difference as both are at

equal distance from 20" pipe line. Then

selection should be based in favour of 8" pump line i.e. saddle 'B' should be

fixed to reduce load on the pump.

Where ever it is possible to make a flexible

piping to the pump, then in such situations, it is possible to make both

the saddles, SLIDING type.

In conclusion fixed

saddle should be so chosen

that expansion of vessel towards

sliding saddle tends

to nullify or substantially

reduce differential expansion passed onto connected pipe line. Fixed saddle should be close to stiff piping

connections to the equipment.

Nice Blog! Helpful for Industrial noise control and solution!

ReplyDeleteAcoustic treatment wa

Nice Post!!

ReplyDeletePlease Look Here At - Push-Fit Pipeline Solutions are revolutionizing the way industries in India approach fluid and air transfer systems. These advanced pipeline solutions are designed to deliver maximum efficiency, ensuring fast installation and long-term reliability. With no need for welding, threading, or special tools, push-fit technology saves both time and cost while maintaining durability. Businesses in India increasingly prefer this solution for its flexibility and ease of use.