Compressors are normally

located inside a permanent shelter or building (Compressor House) for weather

protection. The compressor house can be fully covered by side cladding to grade

level if handling non-hazardous materials e.g. air.

For compressor, handling

flammable materials, ventilation and weather protection is assured by significant openings upto 2.5m ht. at grade level

together with roof ventilators.

Except for lighter than air

gases, trenches, pits and similar gas traps should be avoided within gas Compressor House. This will eliminate chances of suffocation or explosion risk due to accumulation of heavy

gases in pits.

For open compressor house, the side cladding on

all sides should be provided upto 1m below crane level.

The general arrangement of compressor house shall consider

the vendor drawings

and vendor recommendation, if any, for space and location of auxiliary units.

For compressor house where a

number of installations from multiple vendors are to be accommodated,

a thorough discussion should be held among the engineers of Piping, Process and Civil discipline to finalize the detail plot plan

of the unit.

The clear space between compressors shall be minimum 1.5m or half width of the compressors. The clearance between

rows of compressor and at the end of each compressor shall be also 1.5m.Built-in maintenance equipment viz. travelling

gantry with overhead crane / monorail with hoist and chain-pulley blocks

as well as the drop-out

areas shall be provided in the compressor house.

The clearance above the

compressor should be at least 3m more than the longest internal part to be removed.

The substantial space

required for lube oil and seal oil consoles shall be taken into consideration to prepare unit plot plan.

RECIPROCATING COMPRESSORS

Reciprocating compressor generates considerable

vibrations due to unbalanced forces, pulsation etc. For this reason,

the reciprocating compressors should be located as close as possible to the grade level.

The building foundation and

the compressor foundation should be separate to avoid transmission of vibrations from compressor to the building structure.

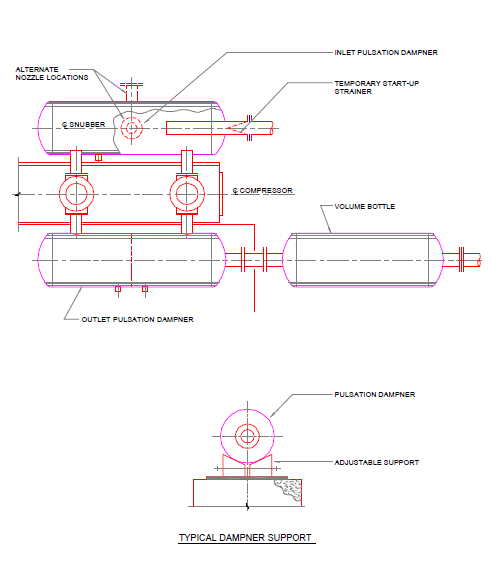

The pulsation dampeners are used to eliminate pulsation

in suction and discharge piping and to separate the source of vibration from the piping system.

The piping arrangement around

the reciprocating compressor should be planned at grade level for ease

of supporting with minimum changes in direction

The grade supports should

be spaced unevenly

to reduce harmonic

motion in the piping.

The piping routed

simply with short

run is less prone to vibration, but at the same time the line should be checked for the flexibility and the

compressor nozzle loadings within the allowable limits furnished

by the vendor.

The piping shall remain clear of the cylinders

and the withdrawal space at cylinder heads.

CENTRIFUGAL COMPRESSORS

The general considerations

for centrifugal compressor layout is same as the reciprocating compressor, exception being that for centrifugal compressor, the

pipeline size is larger, temperatures can often be higher and nozzle

loadings on compressor casing is lower.

The knockout pots, interstage

exchangers can be located at grade outside the compressor house with

auxiliary equipment consisting of lubricating, seal and control oil systems be

placed adjacent to the machine.

The centrifugal compressor

inside a building normally have foundations separate from the building foundation.

The centrifugal compressor with drive are

generally mounted on the concrete table supported on RCC column.

The maintenance facilities like overhead crane

or monorail at the centre

of the compressor bay and the drop-out area

at one of the building or shed is the usual

practice.

If the building is having

installation of several compressors, the height of the travelling crane is to be carefully estimated

so the machine components and rotors can be lifted

over the adjacent equipment.

The compressor suction lines must be free of

any foreign particles that could damage the

internals of the machine. Strainers are installed in the inlet line between

the isolation valve and the compressor inlet

nozzle.

ASME PTC code recommends a

minimum 3 times diameter of straight run piping between elbow and

the inlet nozzle.

The designer shall ensure that all connections shown on the vendor piping

and instrumentation diagrams are properly

taken care in the piping layout. All valves shall be arranged in such a way that

they are accessible from the operating floor around the machine.

AUXILIARY EQUIPMENT

Centrifugal and reciprocating

compressors and their drives require a variety of auxiliary equipment to support their operation. The equipment for these

compressors are discussed below.

Lube Oil Consoles: Compressor bearings receive lubricating

oil from the lube oil console. These consoles

may be either stand alone or be mounted directly

onto the compressor frame. The console consists of lube oil reservoir, oil filters, oil coolers and lube oil pumps.

Seal Oil Consoles:

The hydraulic seals located at the outer ends

of the compressor shaft receive oil from the seal oil console. The seal oil console consists

of seal oil reservior, oil filters and main seal oil pumps.

Inlet Filters:

The inlet filters for air compressors are installed outside the building /shed at a level suitable for clean air suction without any obstruction in the air flow. The vendor drawing of the filter shall be reviewed for correct inlet/outlet ducting and the supporting arrangement.

Suction drum / knockout pot :

As compressors require dry

gas free of foreign particles, it is necessary to pass inlet gas through the suction drum or knockout

pot. This vessel

removes moisture and particles from the gas by passing it through a

demister screen located just below the outlet nozzle.

Pulsation dampener / volume bottles:

The negative

effects of vibration on the life of reciprocating compressors and associated piping can

be minimized by the use of pulsation dampeners (Refer Fig.CHP6). The pulsation dampeners are sized by the compressor vendor and are mounted directly

on the cylinder nozzles.

Volume bottles are used to

reduce vibration. They are located downstream of the discharge pulsation dampener and are similar

to snubbers without

internal baffles or choke tubes.

PIPING ARRANGEMENT

The compressor house piping consist of suction

/ discharge piping, auxiliary equipment piping

and utility system

piping. The main suction line with its components shall

be as short and direct

as possible. The discharge line with its main components shall be routed

clearing the compressor and its driver and supported independent of compressor foundation

or building column foundation. This will minimise the

transmission of damaging vibrations to the building structure / frame.

The vendor furnishes that

P&ID for the compressor with its auxiliary equipment. These drawings should be reviewed

fully for the provisions of vents and drains requirement of the installation.

For reciprocating compressors, API 618 provides the acceptance criteria

for nozzle loads. For centrifugal compressors, API 617 provides the acceptance criteria

for nozzle loads.

Reciprocating compressor

piping arrangement should be finalised after analog study which identifies

potentially damaging accoustic or pulsation problems during design phase itself.

I am really interested in what you wrote here. This looks absolutely perfect. All these tinny details gave me a lot of knowledge.

ReplyDeletegas pipeline inspection

The components of a compressor must be developed for usage with compressed air for the Compressed Air Piping Systems to function correctly.

ReplyDeleteDrone pipeline inspection enhances safety and efficiency by using aerial technology to detect leaks, corrosion, and structural issues, providing real-time data for proactive maintenance and repairs.

ReplyDeleteDrone Pipeline Inspection use thermal imaging and AI to detect leaks, corrosion, and structural issues efficiently. Drones like the DJI Mavic 3 Thermal offer high-resolution thermal and visual imaging, long flight times, and RTK precision, ensuring cost-effective, safe, and accurate pipeline monitoring.

ReplyDeleteGood explanation of Reciprocating Air Compressors and their operating principles. We’ve seen them perform reliably in applications with fluctuating demand, mainly because of their straightforward design and ease of maintenance. A useful read for anyone comparing compressor technologies.

ReplyDeleteEfficient Compressed Air Pipework is essential for industries that rely on pneumatic systems for daily operations. In India’s growing manufacturing and processing sectors, a well-designed piping network ensures optimal airflow, minimal pressure drop, and long-term reliability. Modern systems are engineered to deliver consistent performance while reducing energy costs.

ReplyDelete