INTRODUCTION

Heat Exchangers are widely used equipments in the chemical, petrochemical and refinery type of plant. The control of heat within a plant

operation is done by direct heat application in

a furnace, or by heat exchange in a shell and tube exchanger / plate

heat exchanger. Types of heat exchanger may be Shell and Tube, Aircooled (Fin-Fan), Plate type or Coil type(spiral).

Various process duties of heat exchanger have an effect on the layout aspects viz.

a. Exchange of sensible heat between two process fluids.

b. Cooling with air or water.

c. Chilling with refrigerated liquid.

d. Heating with steam or hot water.

e. Condense by water or a cold process stream.

f. Vapourising by steam (e.g. column reboiler) or any

heat transfer liquid.

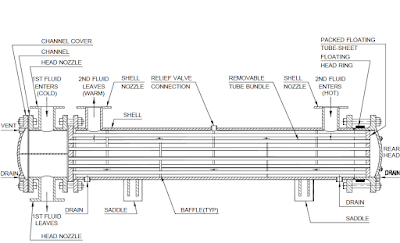

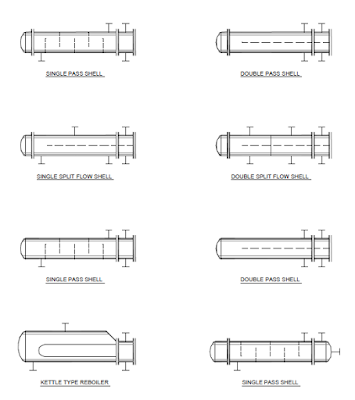

Fixed tube exchangers

are

used

when

the

temperature differences between shell side and tube side

fluid are small.

Floating head or U-type exchangers are used where there is a significant temperature

difference.

Kettle -type reboilers are used for evaporation

in case of

limiting

pressure drop, otherwise

vertical reboilers are used

for evaporation.

Plate heat exchangers

are generally

used in

low-pressure, low temperature

applications. The plate

exchanger occupies less space than shell and tube exchanger for

equivalent heat exchanger surface.

Aircoolers are

used for overhead

condensers of column

and consist of fin-tube bundles with a header

box to each end, having inlet on top of header-box

at one end and outlet on bottom

of header box at the other end.

For single pass arrangement of air-cooler

exchangers, inlet nozzles are mounted on the top of the header box

and the outlet nozzles are located at the opposite end and mounted on the bottom of the header box.For double pass arrangement, the

inlet and

outlet nozzles

are located

at the

same end.

LOCATION

Exchangers should be located

close to the

major equipment with which it is associated in PFD / P&ID. Reboilers are placed next to

their respective towers and condensers are placed over reflux drums. Exchangers between two distant pieces

of process equipment should be

placed at optimal points

in relationship to piperacks.

Most exchangers are to be located at grade

level with elevations to have a

clearance of 1m above Finished Ground Level (FGL). Elevated

exchangers may be necessary to fulfill the NPSH requirement of a downstream

centrifugal pump.

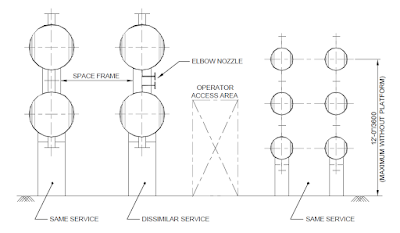

In case of large numbers

of heat exchangers,

they are grouped in one or more category

to save pipe work,

structural work, provision of lifting and maintenance facilities, platform requirement etc. Paired or

grouped exchnagers shall be

spaced to allow minimum 450mm preferrably 600mm between

the outside of adjacent channel or bonnet flanges to facilitate access to flange bolts during

maintenance. Adequate space shall be provided on

either side

of paired exchanger and

at both ends of grouped

exchanger for control and

operator access as illustrated.

Groups of exchangers should be generally

located by the alignment

of channel nozzles in a vertical plane so as to present

an aesthetic appearance.

The support saddle

with oblong holes for provision of thermal expansion are normally

located on the saddle farthest from the channel end but the final location depends on the plant layout and the stress analysis

of the connected piping.

Exchanger piping should be as direct and simple as possible

by considering alternatives such as arranging exchangers side by side / stacking them for reversing flows.

Exchangers are sometimes mounted on structures,

process columns and other equipment. Special arrangements for maintenance and tube cleaning should be provided in such cases.

ACCESS FOR OPERATION

& MAINTENANCE

Internals of heat exchanger require

periodic cleaning and repair. It is important that exchangers and the surrounding piping are arranged to facilitate

access to the internal parts.

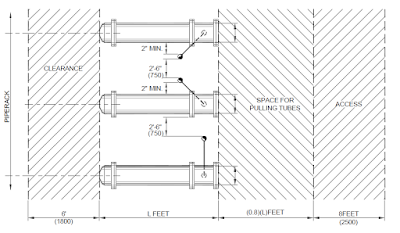

Horizontal

clearance of at least 900mm should be left between exchangers flange to flange or exchanger flanges to piping. Where space is limited, clearance may be reduced between

alternate exchangers but in

no case clearance over insulation between

channel flanges shall be less

than 600mm.

The channel ends of exchangers

should face the local access road for tube bundle removal and the shell

cover should face the piperack. Pulled out bundles

should not extend over

main access road.

A typical

exchanger arrangement with clearance for

access, operation

and maintenance

is shown.

Access for tube bundle removal is usually 500mm more than the bundle length.

Mobile equipment should be used for handling

tube bundles and covers at grade level. Expensive

built-in facilities e.g. lifting

beams, monorails to be kept minimum.

The use of tube-bundle

extractor eliminates the need for permanent tube

bundle removal structures. These mechanisms

weigh around seven tons and are capable of pull

forces about 500,000lbs. The tube-bundle is held in position by crane and balanced

by the extractor's

leveling cradle and pulled out of its shell with pull rod attachments that use

hydraulic force.

For air-cooled exchangers, platform arrangements must suit maintenance

access requirements. Considerations

must be given to fin-tube bundle removal, tube rodding out at header

boxes, motor and fan access.

Provision

of easily removable spool pieces,

flanged elbows, break flanges or short pipe runs will be helpful for maintenance of exchangers.

Illustrations for exchanger location in unit

plot plan alongwith the provisions

of operating and maintenance

space, accessibility are shown.

STEPS TO DO HEAT EXCHANGER PIPING

Collect

the mech. spec. of the

heat exchanger.

Study the P&ID

around the heat exchanger and identify the relationship with the connected equipment

viz. column or reactor.

Note the special process

(functional) requirement along with the specific

arrangement details with respect to level or height difference from other related equipment like pumps.

Study the nozzle schedule, its position on the equipment and verify with P&ID.

Make a

sketch for the relative location and level. Find

out the tube cleaning space in

case shell &

tube Heat Exchanger as well as the maintenance space of tube bundle length.

Locate the control valve stations both for shell side and tube side fluids.

Decide the flanged joints location for replacement of Heat Exchanger / maintenance facility.

Check, in general, that

cooled streams flow downwards

and heated streams flow upwards.

This arrangement is mandatory when

there is a

change of phase, desirable when the streams are liquid but

not

important when the streams

are gas or vapour or

there is no super heating, super cooling.

Check, piping

should not foul with exchanger

removal either in the horizontal direction

for bundle-pulling

nor in the vertical for

whole exchanger removal.

Check, locally mounted PI, TI on equipment or process lines, sight glasses and level indicators are visible from access aisles and valves are accessible from the aisles.

Mark the

supports / support

arrangement on the piping study.

Ensure

accessibility /

operation

facility for all valves as

well as the clearance kept are not less than the

recommended minimum requirement

HEAT EXCHANGER PIPING

SHELL & TUB

After all the required

information has been collected for the

piping design of a heat exchanger, the first step is to outline clearance and working

space in front and around

both ends of the exchanger.

These working spaces should be kept clear of any

piping and accessories to facilitate channel, shell-cover and tube-bundle removal as well as maintenance

and

cleaning.

The free space at the side of horizontal shell can be used for placement of control stations.

The piping is elevated from

grade to have a clearance of 300mm above the grade level. The piping

connected to channel

head nozzles should be

furnished with

break flanges to

facilitate the

removal of

the channel head.

Steam lines connecting to

a header in the yard can be arranged on either

side of the exchanger centerline without increasing the pipe length.

Cooling-water lines, if under ground, should run

right under the lined-up channel nozzles

of all coolers.

Access to valve

hand wheels and instruments will influence the piping arrangement

around heat exchangers. Valve handwheels should be accessible

from grade and from a

convenient accessway. These accessways should be used for arranging manifolds, control valves and instruments.

PLATE & SPIRAL EXCHANGERS

Piping at spiral and plate exchangers

is also arranged

to allow opening

of covers and removal of plates.

Controls at the spiral exchanger are located

on the ends of the unit, clear of the cover plate swing area, piping attachment to cover plate nozzles of spiral exchanger will have break flanges.

Controls for plate exchanger

are located at the front and one side of the

exchanger. The piping is elevated to have clearance from grade as well as convenience for operation of valves.

AIR COOLERS

Piping

for air coolers are not routed

over tube banks or fans

and should be kept

clear of the designated space for motor maintenance.

Following Figure Show Location And Piping Arrangement.

No comments:

Post a Comment