Piping Engineering

Piping Engineering Articles Is Blog To Share Basic Piping Information And Piping Field Material.

Thursday, 4 August 2016

Monday, 1 August 2016

Piping Layout: PipeRack Piping Arrangement Drawing Part-1

The piperack general arrangement

is finalised during the development of overall plot plan. The exact width of

the piperack, numbers of levels and elevations, the access and maintenance

platforms are finalised during piperack piping study.

Normally, the piperack piping

study, with its structural and platform requirements is the first priority item

for detail engineering of a process unit. The piperack may be an integral part

of a process unit located in the middle of the unit or it may be an arterial part

connecting several services of other process unit.

The following data and drawings

are required to be studied before starting the detailed design of piperack

piping study:

Unit Plot Plan / Overall Plot

Plan, Piping and Instrumentation diagrams Plant layout specification, Client

specification, Material of construction, Fireproofing requirements

Wednesday, 27 July 2016

Piping Layout: TankFarm Piping And General Arrangement Drawing Part-2

PUMP LOCATION IN TANKFARM

To determiine the optimum location of pumps, the potential hazards and

client preferrence shall be considered.

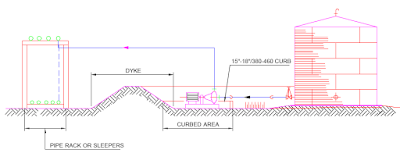

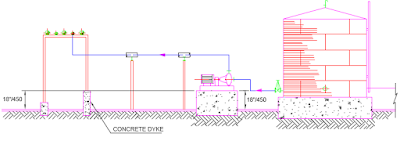

Fig. illustrates the location of pump within the dyke area with the

curb wall height of approx. 400-500mm.

This design protects the pump from minor spillage within the dyke and

enable the discharge piping to exit the dyke over the wall and there is no need

to have dyke penetration seals.

The piping outside the dyke may run on a piperack or sleepers.The pumps

located outside the dyke area are illustrated in Fig.

Tank outlet piping can either penetrate the dyke or pass over the dyke in

case the minimum liquid level in the tank do cause cavitation in the pump.

Tuesday, 26 July 2016

Piping Layout: TankFarm Piping And General Arrangement Drawing Part-1

The study of the tankfarm consisting of a group of tanks shall be carried

out keeping the following basic points in consideration.

1. Grouping of tanks,

2. Specification of the content.

3. Capacity of tanks

4. Nature of hazard - fire

- toxic

- explosive

- corrosive

- bulk handling loading

5. unloading

6. Statutory distance

7. Requirement of Dykewall or curbing

8. Dykewall height or curb height calculation

9. Location of Pumps - inside dyke area

- outside dyke area

10. Approach to tank nozzles with valve

11. Approach to tank roof

12. Drainage of dyke area - Sump and pump

13. Road around tankfarm

14. Fire hydrant / monitor requirement

15. Underground system connected to specific system of treatment / disposal

Thursday, 21 April 2016

Lesson 2 : Basic Of Pipe Stress Analysis Using Caesar II (Model Input Practise)

If you have any doubt than comment...

Tuesday, 8 March 2016

Lesson 1 : Basic Of Pipe Stress Analysis Using Caesar II

From this tutorial you can learn basic concept of caesar 2 software, how to start new file and to create custom unit file for different project.

This tutorial also prove basic theory of strength of material.(F=K*X)

Example show cantilever beam of 10m and having 2mm deflection at one end, other end is fix called as anchor in caesar.

Step1: Create new unit file for this tutorial as shown in video.

Step2: Make 10000mm long pipe in -x direction select a106 grb as a pipe material.

Step3: Select Node number 10 as anchor point and give -2mm displacement in y direction to node number 20.

Step4: Now check for error than run analysis, caesar will show you default load case sus, ope and expansion.

Step5: You can create new load case for only displacement as we required force due to deflection.

Step6: Now see the displacement and force report.

Conclusion: To make 2mm deflection how much force required, that we can see from analysis. and you can also make manual calculation for that to compare using following formula.

F=Kx

where K= 3EI/L^3 N/mm

x= 2mm

If you have any doubt than comment...

Thursday, 7 January 2016

Subscribe to:

Comments (Atom)